Passivation Systems – batch-clean passivation after the electroplating process

WMV Passivation Systems are fully automatic, media-independent and reduce media carryover by 92% after each process step. This makes them an important component that supports you in using resources more consciously – and producing more efficiently.

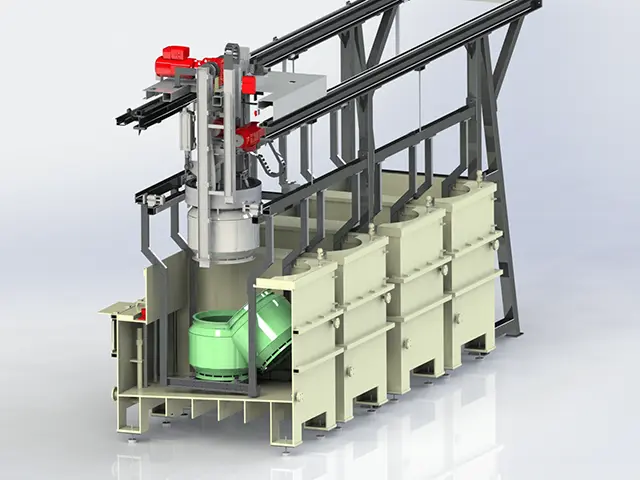

Passivating bulk material in the centrifuge – brilliant results with minimal use of resources

Passivation systems with WMV centrifuge technology can perform any passivation – regardless of the passivation chemistry. They are suitable for all metals and every industry – with responsible use of resources. This is made possible by the rapid centrifuging of the media in the centrifuge bowl. At speeds of up to 750 rpm, media carryover is reduced by 92%. In addition, after centrifuging, the excess medium is returned to the original container and reused. Almost no coating material is lost. And the service life of the passivation tanks is increased: you save costs for energy and chemicals – with the highest purity and quality of your parts.

Clean and gentle – passivating and coating in just one drum

In WMV Passivation Systems, the goods for subsequent TopCoat coating or sealing are already in the drum. This means that the parts do not need to be transferred. Any resulting damage is eliminated. Whether passivation with or without subsequent coating or drying: all the necessary process steps are particularly gentle and are carried out on a batch-by-batch basis.

Find out more about the WMV Top Coat coating

Cleaning and passivation or complex coatings with WMV systems

Fully automated processes – for maximum specification and reproducibility

We have fully customised and automated the passivation process for our passivation systems. This has many advantages:

- High flexibility: Recipes are freely selectable. They fulfil quality requirements for a wide range of parts.

- Full process reliability: Statistics can be called up at any time. Processes are logged and documented. This ensures the quality of your processes and results.

- High reproducibility: Perfect coordination of material and chemistry ensures that you fulfil all quality requirements. Automated processes ensure that you can rely on the consistently high quality of your parts.

- Reduced rinsing processes: In most cases, 3 rinsing processes can be reduced to 2 by centrifuging.

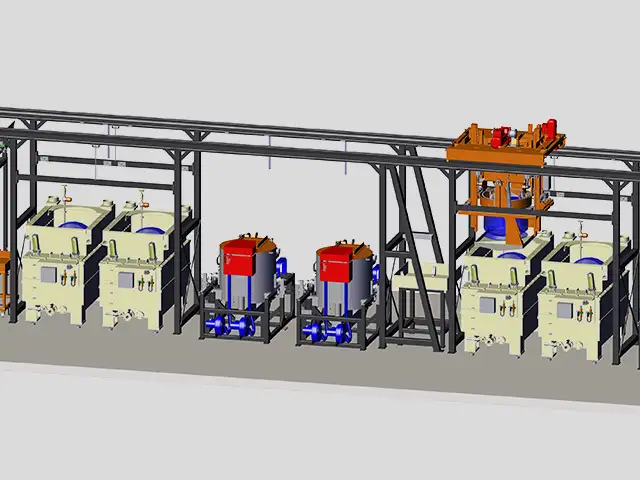

“Always a winning combination” – suitable passivation systems for every system size

From 20 kg/hour to 4 tonnes/hour: The modular WMV system design makes it easy to integrate the right passivation systems for small and large electroplating systems. Regardless of the manufacturer. Including: the energy-efficient WMV centrifuge technology and fully automated processes. This is how we help you to remain competitive and achieve your climate targets – whenever you want.

Good service right from the start – from enquiry to integration and aftersales

WMV has been impressing customers for over 50 years with its streamlined processes and personalised support – worldwide. A competent contact person is available to you for all process steps. Our after-sales service is there for you – for as long as you wish:

Good service right from the start:

- 24-hour hotline service

- Maximum availability of your passivation systems

- effective maintenance

- fast response time

- Customised training

Suitable Passivation Systems from WMV –

a benefit for every process step

As efficiently and gently as possible, we use WMV centrifuge technology to ensure that you improve your surface finishing processes with an eye to the future and the environment.

Frequently asked questions

Is the passivation step necessary for all parts in the electroplating process?

This varies from case to case. Passivation can be the final step in the electroplating process or an important step in preparation for subsequent surface finishing.

How flexibly can your passivation system be integrated into our electroplating processes?

Thanks to their modular design, our systems are completely flexible in terms of adaptability and recipe for all parameters and any process sequence.

For which components and surface finishing processes are your passivation systems suitable?

Bulk goods and rack goods can be passivated in our systems. They are suitable for all operators of electroplating systems in contract coating and parts production as well as for in-house coaters.

Do you have any questions about WMV Passivation Systems?

WMV Apparatebau GmbH, Windeck – We look forward to hearing from you