Tempering systems – flexible and efficient tempering after electroplating

WMV Tempering Systems integrate perfectly into the post-treatment processes of your electroplating shop. They temper in all performance levels. In different tempering times. Are flexible in the processing of bulk material and mass-produced goods. And thanks to the symbiosis of centrifuge technology and a high level of automation, they are more efficient than ever.

Temperature control systems – prevent hydrogen embrittlement

The properties of metallic materials are specifically optimised through heat treatment or tempering. Their chemical and temperature resistance is increased and stresses in the material structure are reduced. The reason: targeted tempering causes the hydrogen to diffuse out of the component. This prevents damage or embrittlement caused by the hydrogen, homogenises the structure and increases the service life of the components.

Post-treatment and tempering

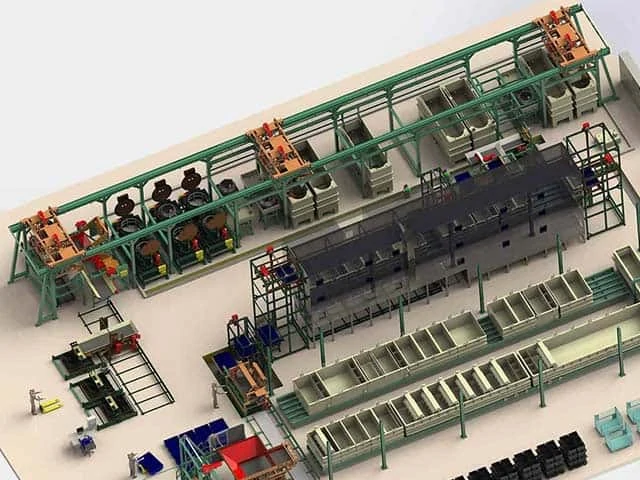

With the modular WMV systems, the tempering process is integrated into the electroplating post-treatment and the entire process is seamlessly documented. When loading a plating line, our loading systems automatically transfer the respective partial batches from the horizontal plating line to the vertical WMV drum. These partial batches complete the entire process from electroplating, tempering and the desired post-treatment, e.g. TopCoat coating, to unloading.

Are you interested in a tempering system?

Heat treatment in plant systems from WMV Apparatebau Windeck. We will be happy to advise you!

Tempering systems from WMV – batch-clean tempering according to CQI-11

The actual tempering process takes place in corresponding oven systems. Here, oven racks are pushed through the tempering oven from the outside in cycles on several levels, thus enabling a high level of batch purity. The requirements of CQI-11 are also fulfilled. The corresponding WMV dosing and transport systems ensure perfect material distribution in the oven racks as well as loading and unloading of the tempering oven in line with the cycle time.

Tempering furnace – always a perfect addition

We work closely with manufacturers of tempering furnaces and supply them as the perfect complement to our electroplating and post-treatment systems. Our tempering systems focus on energy efficiency, sustainability and resource conservation. Energy-efficient drives are selected with the ideal energy efficiency class. The braking energy of the drives is fed back into the grid via innovative frequency converter technology. Intelligent solutions minimise the consumption of expensive process media and valuable resources. Intelligent control technology and the high degree of automation of the processes enable our customers to realise different temperatures and holding times depending on the process.

High degree of automation in the WMV system

The tempering systems are also designed with a high degree of automation and customised to customer requirements. This has many advantages:

- Constant throughput

- High reproducibility

- High degree of customisation to your requirements

- Transparent logging

- scalability

- Complete traceability

- 3D visualisation

- individual evaluation

- Analyses in real time

- Continuous analyses

- (double!) PLC control and remote maintenance

Good to know: For heat-sensitive passivations / top coats, the tempering furnace can optionally be installed directly after electroplating, i.e. before passivation. You will achieve the best result if you continue the tempered goods afterwards with the WMV technology of passivation and coating

Batch purity for your industry

Coating Composite materials Metal industry Other industries – we know our way around

Questions & Answers

What is meant by holding time?

The holding time during tempering is the time that the workpieces and components must be held at a constant temperature in the tempering furnace. Depending on the part, the holding time is 8, 12, 24 or 48 hours.

What is tempering?

Tempering is the specific heat treatment of metallic solids over a defined period of 8, 12, 24 or 48 hours. The aim of tempering is to achieve a uniform surface quality of the workpieces and components in order to improve the durability of these parts.

How does tempering work?

The tempering process is integrated into the electroplating post-treatment. The material is transported to a chamber or continuous furnace via a transport system. And this is where the tempering process begins. The furnace heats the material over a longer period of time and is then automatically removed again via a transport system.

Do you have any questions about WMV Tempering Systems?

WMV Apparatebau GmbH, Windeck – We look forward to hearing from you