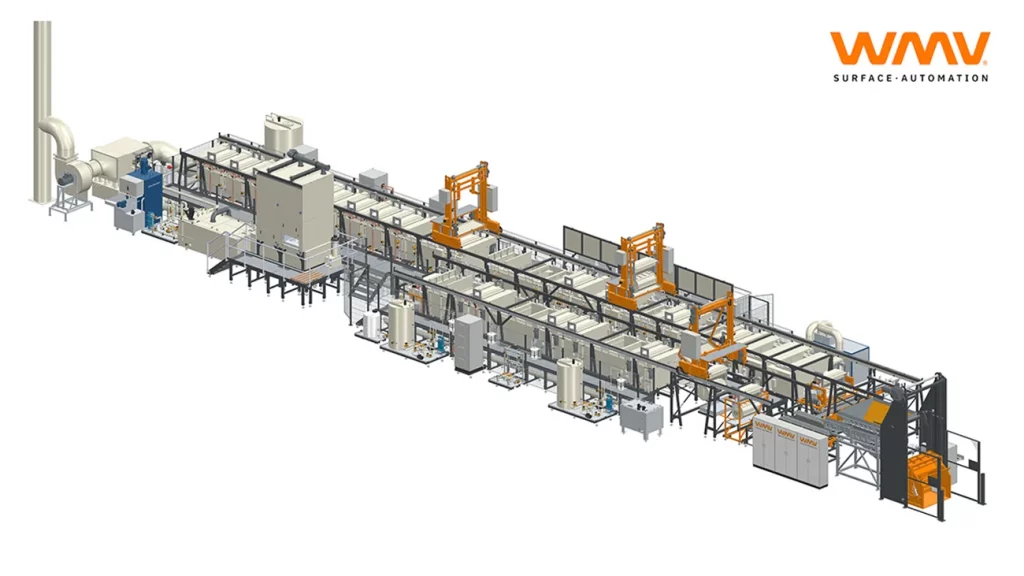

Modular electroplating systems are WMV’s solution for innovative, efficient, and future-oriented system design.

Preconfigured modules significantly reduce planning time, manufacturing, and assembly compared to conventional systems. Lower engineering and assembly costs reduce investment costs many times compared to conventionally designed electroplating systems. In addition, interface optimization, compact design, and high system reliability reduce investment and follow-up costs in the long term — while at the same time enabling each system to be tailored precisely to your specific needs.

Complete solution for process optimization with barrel plating as needed

Complex projects are often subject to high pressure — with tight schedules, tight budgets, and demanding interfaces. Conventional plating systems are often too rigid and expensive, leading to delays and increased risk. “We wanted to solve this problem for our customers,” says Michael Kamp, Management Board Sales at WMV. And we did so with existing solution concepts ‘made by WMV’.

“The basis of WMV plant engineering is a well-thought-out modular principle that combines a high degree of flexibility and adaptability with a high level of implementation expertise,”

Michael Kamp, Management Board Sales at WMV

With our expertise in electroplating technology, we are now also able to plan complex coating systems and customize them as required—both with conventional barrel plating in a barrel unit and with WMV centrifuge technology in the area of pre- and post-treatment systems.

Efficiency for new and existing plants

Thanks to our extensive and diverse product range, we can cover the entire process chain in the field of surface treatment systems.

“As a 360° company, we manage all relevant interfaces and deadlines centrally. There is no need for coordination between individual suppliers, which significantly reduces the project risk for our customers,” explains Detlev Kroes,

electroplating expert at WMV.

The WMV modular system also offers clear advantages for operators who want to expand their existing electroplating processes in a future-proof manner. “Those who already use WMV centrifuge systems for pre- and post-treatment will be able to seamlessly combine them with the drum electroplating modules in the future,” says Kroes. In addition, with the 360° WMV solution for electroplating systems, our customers benefit from our consistently reliable 24/7 service, including support and maintenance. Finally, WMV’s modular technology impresses with additional parameters that are specifically designed for greater efficiency and process optimization right from the planning phase.

Shorter development and assembly times

Early and transparent visualization of technical information enables all project participants to make decisions much more quickly, which speeds up implementation. In addition, the modular design allows preconfigured modules to be assembled into a complete system and tested in advance at our WMV production facility in Windeck. This means that individual adjustments can be coordinated with our customers at an early stage and implemented quickly.

The innovative modular design also significantly reduces assembly and commissioning times. This comprehensive reduction in development and production costs ensures increased cost efficiency.

Our modules are designed to allow a high degree of customization in barrel plating. Thanks to the WMV modular system, we are also able to meet special requirements. This ensures the necessary planning reliability while maintaining a high degree of flexibility,” says

Detlev Kroes, plating expert at WMV.

Advantages of WMV modular technology at a glance:

- Time savings: Preconfigured modules accelerate planning and implementation.

- Cost reduction: Less engineering effort and fewer interface errors reduce project costs.

- Interface optimization: Perfectly coordinated modules minimize integration risks and increase operational reliability.

- Planning reliability: 3D visualizations and preliminary tests enable early commitment from all relevant stakeholders.

- Flexibility: Modular design enables integration, even into existing WMV centrifuge technologies for pre- and post-treatment.

Practical implementation and compact design

What makes the modular design of our electroplating systems so special? “During development, particular attention was paid to optimizing the interfaces, a compact design, and a technically safe solution,” says Kroes.

Optimized designs and the interaction of responsible components have significantly improved the transfer processes. In particular, loss and damage to the customer goods to be coated has been significantly reduced.

What’s more, space costs money. This approach has resulted in a compact design for the electroplating system and the necessary components. Whereas rectifiers and drain tanks, for example, are often located away from the system, in our solutions they are directly assigned to each process bath and located in the immediate vicinity.

In addition to practical implementation and compact design, consistent compliance with DIN 17059 is also a key focus in the design and implementation of electroplating systems. This standard requires that systems and their components be selected and installed safely. “We at WMV attach great importance to this,” says Kroes. In addition, we have incorporated preventive fire protection into our system development from the outset. Fundamental measures that should already be state of the art today were taken into account preventively in the design.

Are you planning a new plant project? Your contact Detlev Kroes is available to answer any questions you may have about the design and implementation of your electroplating systems. On request, we can also create a customized specification sheet for you.

Detlev Kroes, Sales & Projects