Thanks to robotic automation, the PULZ® Xtend increases productivity to 7,500 kg/hour – in a continuous 2-minute cycle. Around the clock. With consistent precision and coating quality. As usual, the coating of the goods is gentle, flexible, and uniform in its results.

We already set new standards with the development of our WMV planetary circulation painting centrifuges PULZ® Xtreme and PULZ® Xtend consistently high coating quality, maximum flexibility in terms of shape, size, and material of the parts, and media savings of up to 30%.

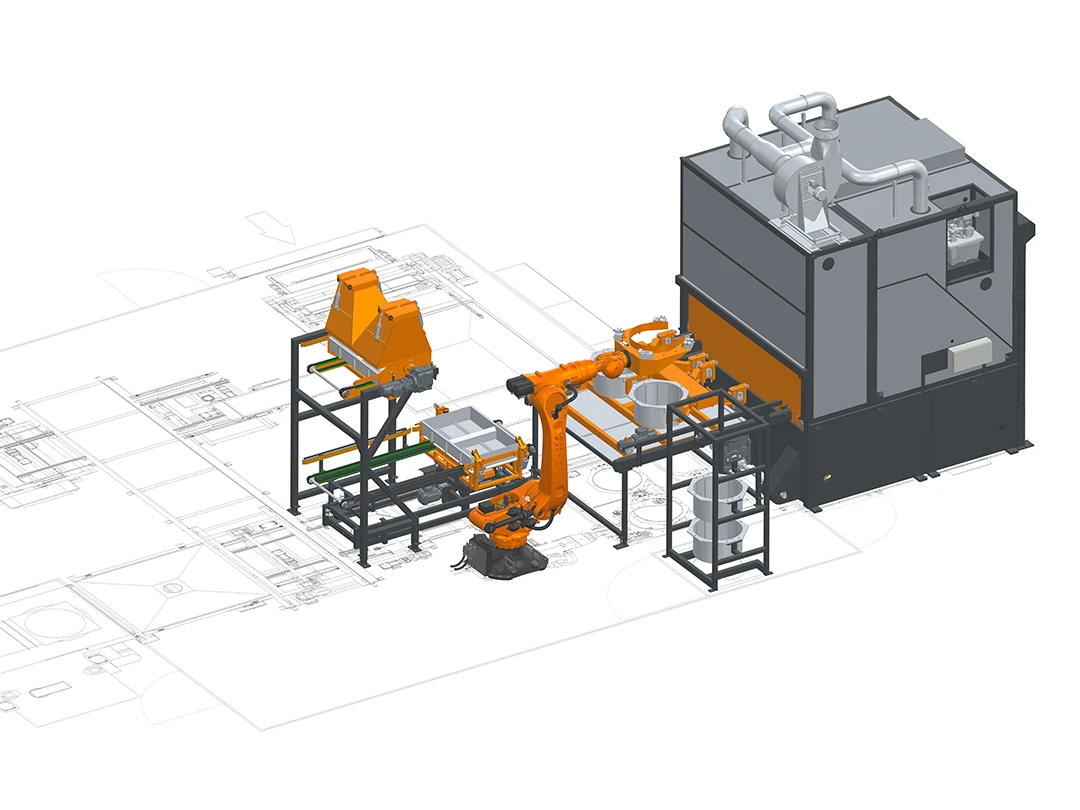

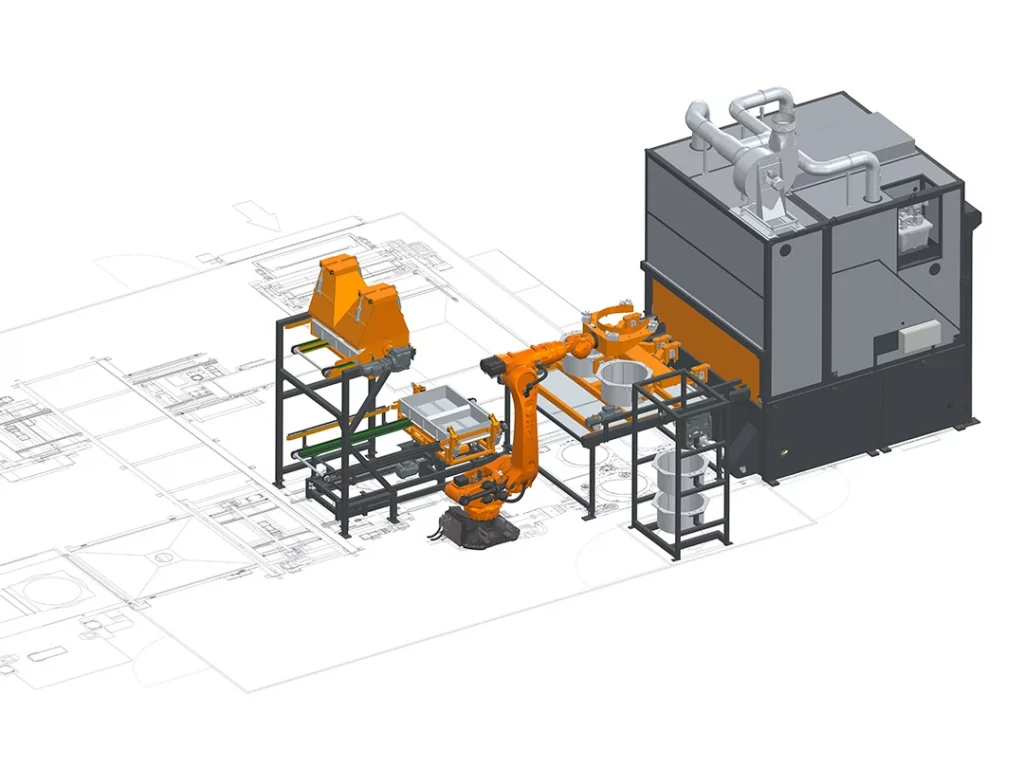

Now, the latest evolution of PULZ® Xtend marks the next milestone: by combining WMV’s innovative basket exchange system with robotic automation for basket handling, we can significantly improve performance per coating layer to a total of 7,500 kg/hour – while maintaining a stable cycle time of just 2 minutes. In addition, design enhancements have increased the basket volume and, accordingly, the load weight from 200 kg to 250 kg per batch.

Robot automation: Coating and loading go hand in hand

What is the idea behind robot automation in the coating system?

“With PULZ® Xtend, we have already significantly increased the performance and efficiency of the coating system. The aim of integrating robotic automation was to increase performance even further, reduce the cycle time from 3 to 2 minutes, and now use the 2-minute cycle time even more efficiently,” says Michael Kamp, Management Board Sales at WMV. More efficient in the sense of even more productive, gentler, more flexible, and more consistent results.

To achieve this, robot automation is used to integrate several processes simultaneously – some inside and others outside the coating station: Inside the PULZ®, the goods are coated with absolute uniformity and the coating baskets are changed using a basket exchange system. At the same time, a robot outside the PULZ® takes over the completely automated, material-friendly unloading and refilling of two additional coating baskets. The exchange of coating baskets is smooth, and the material flow is uninterrupted.

“Thanks to the interaction between robot automation and our basket exchange system, the coating plant can be reloaded in a material-friendly manner while the previous batch is still being dosed. This allows us to continuously maintain a cycle time of 2 minutes—and permanently increase overall output to 7500 kg/hour.”

Michael Kamp, Management Board Sales WMV

Another advantage: handling in divided trays, known as split trays, means that the sub-batches are retained throughout the entire process. The batches only need to be dosed once at the beginning.

Here you can see the process in action

PULZ® technology meets robot automation: innovation with many advantages

What makes PULZ® technology so efficient and this innovation so unique?

The technological advantage of PULZ® technology is based on the fact that the centrifuge reaches a centrifugal force of up to 32 g within seconds of the parts being immersed. With simultaneous repositioning of the goods, item-specific centrifugation removes excess coating medium from every single point on the goods to be coated. Even the smallest undercuts are coated cleanly and evenly – with up to 30% less media consumption. The coating medium is collected and returned to the process.

“In combination with robot automation, the PULZ® Xtend is the world’s first coating system that can coat batches of up to 250 kg in a continuous 2-minute cycle at high centrifugal force and simultaneous position change.”

Johannes Dittmann, Sales & Project Engineer WMV

Performance data at a glance

| Cycle time: | 2 min |

| Batch weight up to: | 250 kg (2 x 125 kg) |

| Batch volume up to: | 160 Liters (2 x 80 Liters) |

| Output per coating layer: | 7500 kg/h |

Coating quality: Gripping the baskets without contact with the coating medium

How is media carryover prevented in robot automation?

Media carryover is prevented by a specially developed robotic gripper. It grips the baskets only by their upper ring. This prevents contamination of the goods with foreign media. “The robot with gripper is also used to replace the baskets, for example, when the medium is changed or the baskets are dirty,” says Kamp. Other processes such as basket cleaning can also be integrated as automated processes.

Software development by WMV: Robot automation adaptable to customer requirements

How flexible and reliable is the software for individual coating processes?

We also developed the software for robot automation ourselves. This enables us to precisely map customer-specific processes and adapt them to changing requirements at any time. The system becomes even more flexible and safer to use. With our 24/7 hotline service, our customers can rely on fast support, especially for the robot.

Maximum flexibility: Space-saving design and fully integrable into the WMV modular system

Thanks to its space-saving configuration, the robot module can be adapted to any system, individual processes, and goods. Both in stand-alone systems and in the WMV modular system. Integration of the robot solution into other WMV systems for surface treatment is possible. “Before the final decision is made, we create a realistic 3D simulation of the system for our customers,” says Kamp. This virtual 3D model shows in advance how the coating system with robot automation will work in practice.

Advantages of PULZ® Xtend with robot automation

- Highest coating quality even with demanding part geometries

- Continuous 2-minute cycle for 250 kg batch weight

- Reproducible quality

- Maximum flexibility in terms of shape, size, and material of the bulk material

- Reduced media consumption by up to 30%

- Precise control for reproducible results in every cycle

- Gentle material flow thanks to automatic regulation of drop height and reduced transfer processes

- Reduced media carryover thanks to special basket handling

- Reduced dosing and transfer processes thanks to split trays

- Fully integrable into the WMV modular system

- Improved footprint thanks to reproducible results and optimized resource consumption

Do you have any questions? We would be happy to give you a personal presentation of our PULZ® Xtend coating system with robotic automation. Arrange your personal appointment here with

JOHANNES DITTMANN, SALES & PROJECT ENGINEER