Coating system

PULZ®

PULZ® planetary circulation painting centrifuges for surface treatment

PULZ® coating systems for the surface treatment of bulk materials remove excess coating media before it dries. Media savings of up to 30% are possible. For the smallest fasteners with internal force application with the PULZ® Xtreme. For standard sizes with the PULZ® Xtend. Always from 0 to 180 rpm in 5 seconds!

Coating with the PULZ® surface treatment at 32g acceleration

The PULZ® coating system was developed in 2020 in close cooperation with a leading global manufacturer of fasteners. The patented technology of the PULZ® makes it possible to accelerate the goods from 0 to 180 rpm in 5 seconds after immersion in the exchangeable coating trolley. This is done while simultaneously changing the position of the goods.

Advantage: Due to the high centrifugal force (32g) and simultaneous change in position of the product, media layers are distributed homogeneously over the entire surface of the part. This can save up to 30% of the media consumption.

PULZ® technology – always a winning combination

- Fully automatic

- space-saving

- Can be fully integrated into the WMV modular system

- Can be fully integrated into process chains

- Complete coating of bulk goods (small parts and standard parts)

- resource-saving

PULZ® Xtreme – maximum coating quality for minimum sizes

The PULZ® Xtreme coating system was developed to improve the coating quality of very small parts with internal attack at high throughput. With a speed of 180 rpm and simultaneous change of position of the goods, the PULZ® Xtreme coats up to 120 kg of bulk material per batch evenly – right down to the interiors of the smallest parts such as M3 screws (Allen/Torx).

Are you interested in the PULZ® ?

We will be happy to advise you!

Zinc flake „One step further“

PULZ® Xtend – best results in surface treatment for all sizes

With the PULZ® Xtend, we have adapted all the advantages of PULZ® technology for contract coating and in-house coating of bulk goods. Regardless of the industry, bulk goods can be coated completely evenly with the PULZ® Xtend – up to 200 kg per batch and up to 30% media savings.

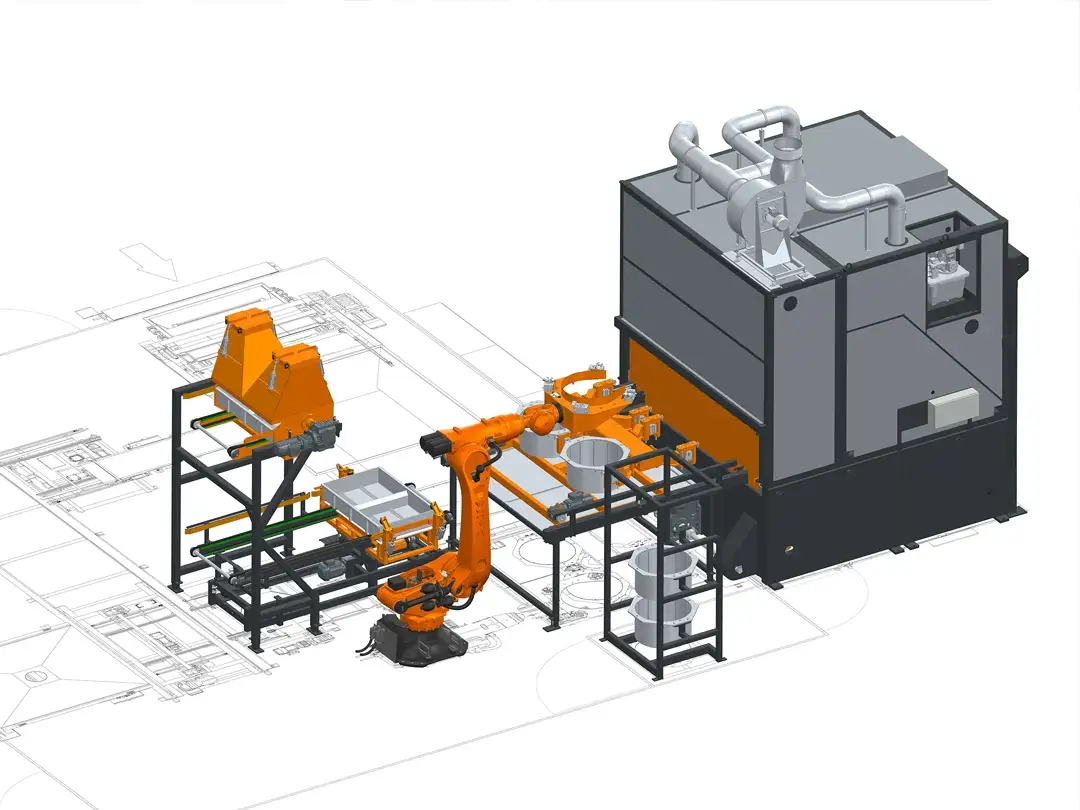

PULZ® Xtend with robot automation – performance boost per coating layer up to 7,500 kg/h

In combination with the innovative WMV basket exchange system, automated loading of the PULZ® Xtend coating system with a robot enables clean and precise coating of the goods in a continuous 2-minute cycle – up to 250 kg per batch (7,500 kg/h) with up to 30% media consumption.

Efficiency boost through automated robot loading and basket exchange

The video showcases the innovative basket exchange system technology, enabling a loading cycle every 2 minutes – including automatic loading of the subsequent container for maximum productivity.

Efficiency with the highest quality

even with the smallest internal force attacks

Even for parts with internal force application in the order of M2, the coating achieves maximum gauge retention. High acceleration and simultaneous position change ensure uniform coating thickness distribution over the entire surface with the different geometries such as thread, head, internal engagement, etc.

30% savings in media consumption compared to conventional coating processes nevertheless lead to higher quality and outstanding corrosion protection properties.

Get the practical PDF data sheet on PULZ®

Innovative coating process for very small parts

State-of-the-art system technology sets new quality standards in the zinc flake coating of very small parts.

The PULZ® can be integrated into the WMV modular system

The coating station can be combined with the tried-and-tested WMV assemblies both as a stand-alone application and as a fully automated system with integrated pre-treatment and material and coating drum handling. Belt, batch or tray furnace systems can be used.

Questions & Answers

How can coating baskets be exchanged in coating systems?

The coating baskets are exchanged automatically. Compared to other coating systems for very small components, the PULZ® only works with 2 instead of 4 coating baskets. This eliminates more than half of the cleaning effort when changing the coating medium.

How can the smallest connecting elements be coated?

WMV Apparatebau GmbH has developed the innovative PULZ® process for coating the smallest fasteners. This enables the product to be spun at 32G while simultaneously changing its position. This process enables even the smallest parts with internal attack to be coated to a very high quality (uniform layer formation / and free internal attack).

What is a PULZ® ?

A PULZ® is a planetary circulation coating centrifuge. This coating system was specially developed by WMV Apparatebau GmbH for the high-quality coating of very small parts. The PULZ® is one of the 4 modules in WMV Apparatebau GmbH’s catalog of modular coating systems.

WMV is available for you worldwide

Newsletter

Get exclusive insights and news from the WMV Surface Automation world and sign up for our newsletter.