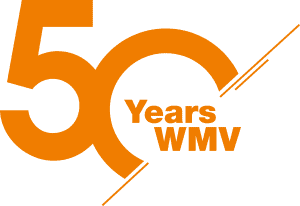

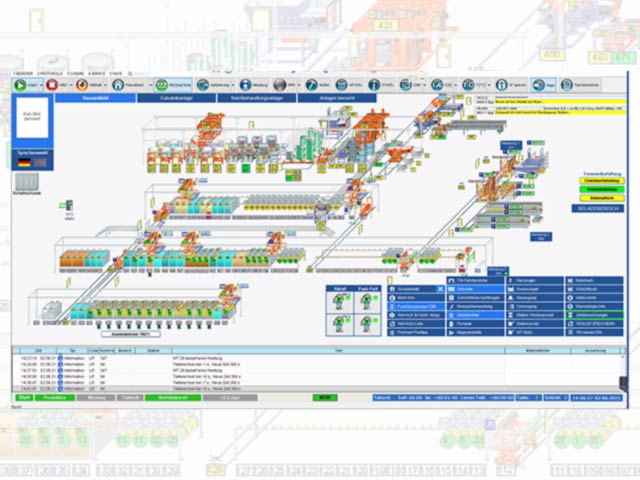

Production Control System

Production Control of different plant types, such as for interlinked plants, Production Control of pre-treatment

machines up to post-treatment plants with the master computer.

Integration of WMV systems into the customer’s existing Production Control systems

Regardless of whether a new WMV system is to be integrated into an existing WMV system at the customer’s or into systems from other manufacturers. In consultation with the customer, WMV always looks for the best solution for efficient and smooth

Production Control for the plant operator.

The master computer for

Production Control

Master computers also provide a human-machine interface (HMI) to PLC Control systems and offer even more advanced functionalities than the operating devices. Depending on the configuration of the host computer, the customer has a wide range of options for plant optimisation and process optimisation. Protocols generated by the host computer, such as production protocols or fault protocols, can be beneficial. Treatment programmes can be managed and maintained centrally on the master computer across all plants if the project planning is appropriate.

Production Control – everything at a glance

A plant overview of the entire plant or individual plant areas is often available on a master computer, which allows a quick overview of an area or an entire plant. This can be helpful for remote control systems to support the customer “from a distance” in optimising the system, optimising processes or analysing faults and the documentation of production is also ensured by master computer systems, as this is now a frequent requirement. This way, production protocols can be saved for years and retrieved by the customer at any time.

All tuned…

In order to ensure smooth Production Control across all plants, the customer, the WMV specialists, the manufacturers of the third-party plants, the master computer supplier and any other contact partners that may be required are involved in discussing and implementing all points that may be necessary for Production Control across several plant areas.

Are you interested in WMV Production Control?

We will be happy to advise you!

Worldwide contact to WMV Apparatebau

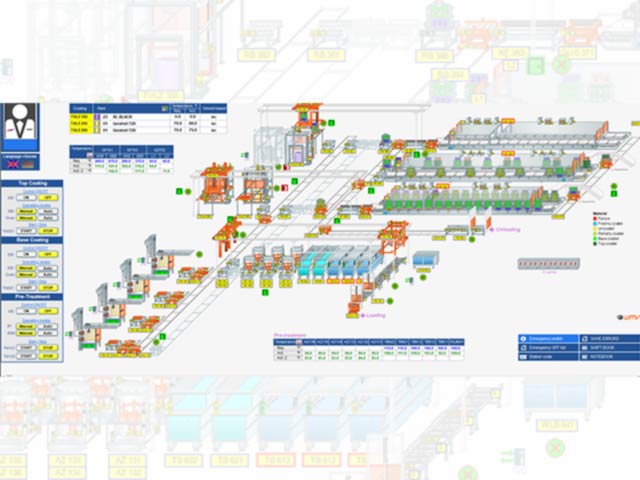

Interlinked systems

WMV systems in use

Large WMV plants can also consist of several interlinked areas. Likewise, WMV systems can also be integrated into existing or new systems at the customer’s site. The integration can occur both in an existing WMV system at the customer’s site and in systems from other manufacturers.

In both cases, depending on the purpose of the WMV plant, a distinction is made between pre-treatment plants, intermediate treatment plants or post-treatment plants or a combination of these plant types.

When plants fill entire halls….

In large plants and especially in interlinked plants, Production Control is therefore of particular importance. For this reason, higher-level master computer systems are almost always used in these plants.

These can consist of several computer workstations, e.g. a computer in the office and one or more computers at the plant or the plant areas.

Do you have questions about Production Control?

We will be happy to advise you!