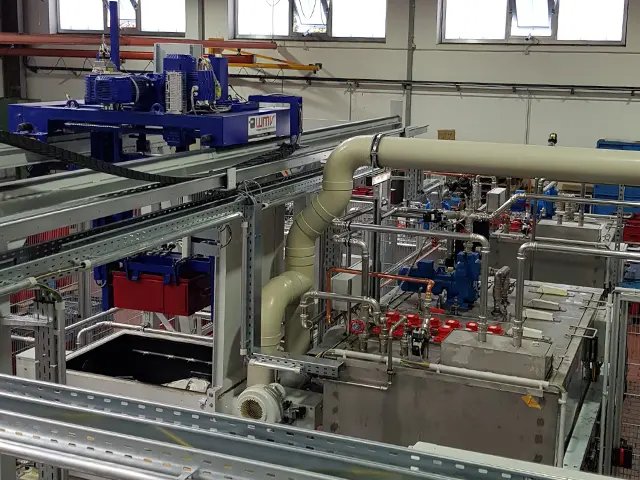

Industrial cleaning systems – customised concepts for greater flexibility and efficiency

Cleaning systems from WMV wash, rinse, dephosphatise, de-oil and dry bulk goods and racked goods gently and individually. Thanks to the modular system design, our washing systems can also be perfectly integrated into your logistics as a stand-alone solution. The individual stations adapt perfectly to all upstream and downstream processes and are scalable at any time: you get the right solution for your challenges – and remain ready for the future.

A universal system concept for every challenge

In contrast to most cleaning systems, WMV solutions with centrifuge technology adapt flexibly to the local conditions, the respective range of parts and the existing processes. On top of this, we enable gentle loading, including the right dosage for your bulk goods and gentle unloading. So you don’t just get a cleaning system, but a consistent system concept that integrates perfectly into your logistics. And adapts to your throughput times. As efficient as possible – and as automated as you want it to be.

How WMV centrifuge technology works – fast, effective and energy-saving

Drying by centrifugal force, combined with a circulation process, enables significantly better heating and drying of the parts. The swivelling centrifuges are also equipped with a humidity measurement system. Here, the heating power is regulated according to the measured humidity in order to avoid the unnecessary use of heating energy. Sustainable plus: The cleaning process generates braking energy, which is fed back into the energy network using WMV technology. This significantly minimises energy consumption – by up to 80 %.

WMV cleaning systems stand for optimum results in parts production for

- Pre- and intermediate cleaning in hardening technology

- Pre-treatment in electroplating

- Pre-treatment during zinc flake coating

- after salt bath hardening (bainitising)

- in tempering processes for bulk goods and mass-produced goods

“Always a winning combination” –

The right cleaning system for every process stage

The WMV modular system for cleaning systems adapts to the current performance of your processes and can be scaled individually. Would you like to customise your existing processes? Integrate WMV’s globally proven expertise into all stages of parts cleaning and benefit from many advantages with a WMV cleaning system:

- High reproducibility

- individualised timing

- Maximum energy efficiency

- 95% less media carryover between all process steps

- Almost no waste water

- Maximum recycling of media

- Integrated container washing system

- Automated and manual processes possible

- for all system types

Worldwide contact to WMV Apparatebau

Industrial cleaning systems from WMV

The WMV modular system from a single system to complex road systems

WMV cleaning systems – every station is an asset

Getting the hang of cleaning: The ability to spin the fabric within the wash and rinse stations minimises carryover between the wash and rinse media in the individual stages. This further reduces the consumption of chemicals and water. This concept enables long service lives of the washing media of up to 6 months and therefore high economic efficiency of the cleaning systems.

Rinsing –

Salt bath hardening / Bainitising

Our salt rinsing system not only helps you to rinse clean after salt bath hardening, but also to clean in an environmentally friendly way. This is made possible by a clever centrifugal process in which up to 95% of the salt is recovered from the salt bath and reused. This conserves your resources and parts in the long term. And saves you time and money.

De-oiling –

cleaned before cleaning

In our systems for de-oiling bulk goods and rack goods before the washing process, up to 95% of the oil can already be spun off the goods to be treated and therefore does not contaminate the washing media in the cleaning systems.

Dephosphatising – for

for batch-clean results

In our dephosphatising systems, we ensure that, in addition to the effect of the cleaning agents, a mechanical effect is also exerted on the fabric by the circulation during the washing process.

This is comparable to the process of washing hands.

Drying –

A well-rounded solution for the best results

In our drying systems, we use our centrifuge technology, which has been tried and tested and continuously optimised over many years, to dry washed and rinsed parts. Here too, the advantages of the modular WMV system are fully utilised. WMV drying centrifuges are ideal for standard goods. For parts that are difficult to dry, tightly packed or scooping, we use the tried and tested swivelling centrifuges in our cleaning systems.

Customised automation solutions – for

for sustainable processes and optimum results

With our know-how and expertise, we accompany you on your way to greater efficiency in automation. From loading to unloading, if you like. We also make completely unmanned processes possible. You benefit from

- Complete traceability

- 3D visualisation

- individual evaluation

- Analyses in real time

- Continuous analyses

- Scalability

- PLC control and remote maintenance

Perfectly connected –

PLC control and remote maintenance

The PLC control system with touch screen panels used in our cleaning systems offers a high level of user-friendliness and optimum support for troubleshooting and maintenance. Like all WMV systems, PLC controls have an Internet connection that enables remote maintenance. This means that WMV specialists can quickly help with any troubleshooting. With an optional 24-hour on-call service contract, support from specialised personnel is available 24 hours a day, 7 days a week.

Play it safe – test your

test your cleaning system in the WMV technical centre!

At the WMV technical centre, we work with clients and media manufacturers to continuously develop cleaning processes in the industry. A cleaning system for test runs is also available for your task. You will be accompanied by technical experts and engineers. The practical test shows you the benefits of using a WMV cleaning system. And gives you the certainty that the system fulfils the quality of your requirements.

WMV cleaning systems –

for customised industrial parts cleaning

WMV cleaning systems ensure the optimum cleaning quality of bulk materials and bulk goods in the long term: they consume less energy and resources. And they can be seamlessly integrated into bursting processes and logistics – and can also be retrofitted at any time.

Questions & Answers

How high are the energy savings in WMV cleaning systems?

The achievable energy saving for the drive unit in question can be up to 80%. The application is particularly useful where, due to the system, high speeds frequently have to be braked to a standstill and then accelerated again, e.g. in centrifuges, washing and rinsing stations. WMV’s industrial systems are tried and tested and feature special cleaning technology.

Is batch separation possible in a cleaning system?

Yes, specially designed centrifuge drums, which are fed in and out of WMV Apparatebau cleaning systems, ensure that there is no mixing of batches in the system.

Which products can be cleaned in a cleaning system?

In an industrial cleaning system, components and small cavity parts such as screws, nuts, washers, bent and stamped parts etc. are cleaned quickly and thoroughly.

What is an industrial cleaning system?

Industrial cleaning systems are specially designed for cleaning bulk goods and rack goods. They remove oil, grease and phosphate layers from screws, nuts and similar small components and prepare them for subsequent coating. The degree of cleaning is decisive for the quality of the coating.

Do you have questions about WMV systems?

Do you have questions about WMV systems?