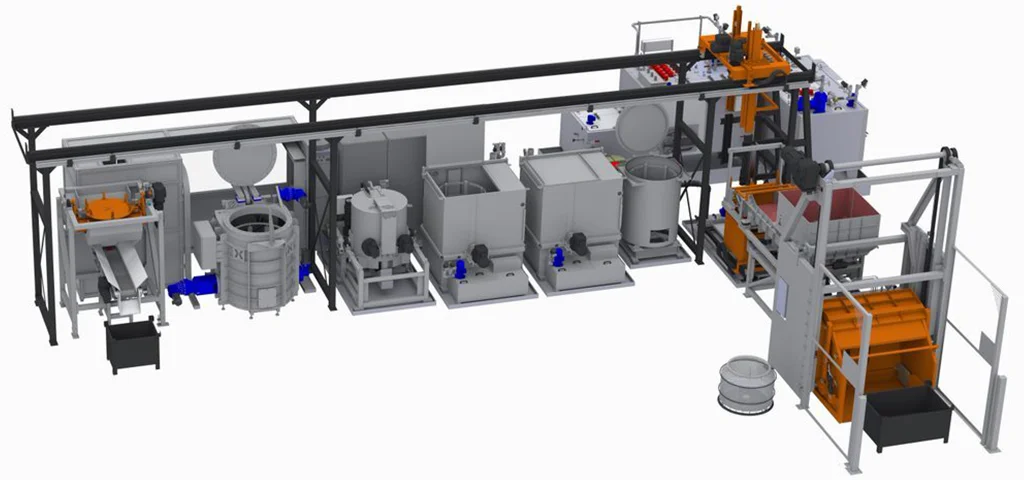

WMV and aixACCT revolutionize bulk solids preparation with innovative plasma cleaning technology

The cooperation between WMV and aixACCT has resulted in an ideal combination of pre-cleaning and ultra-fine cleaning, which enables optimal preparation for subsequent surface treatment.

Whether nails, screws, bolts, washers, clips or bushings the plasma cleaning effectively activates the surfaces of small parts made of metal or plastic. The system developed by aixACCT mechatronics removes even the last, stubborn dirt. Thus, the parts are perfectly prepared for the subsequent process, whether coating, painting or galvanic treatment.

The PFI 900 can be operated as an integrated component of a WMV cleaning system and as a stand-alone solution. Read below to find out which advantages you have over the entire washing process in a WMV system, including plasma cleaning:

Gentle movement / clean washing

In WMV cleaning systems, the drum is brought into washing position, i.e. inclined position. During the addition of washing medium, the drum starts to rotate. The decisive advantage of our cleaning system is that the parameters are individually adjusted for each article, thus our systems meet all the needs of any group of parts with individualized washing programs and drastically reduce energy consumption, since after each washing process excess washing medium is returned to the cleaning tank by centrifugal forces.

Sustainable rinsing

The rinsing process runs in the same way and under the same setting options as the washing process. The only difference is the shorter treatment times. In principle, several rinsing processes are provided. It is important that all rinsing processes are also switched in cascade with the washing process. After each rinsing process, the excess medium is spun off to prevent carryover of the medium to the next process. Thus, cleanliness is kept as high as possible.

Efficient drying

During drying, the advantage of the WMV industrial centrifuge system again comes into its own. As a process of circulation and centrifuging is realized by the swing centrifuges, any kind of articles can thus be dried quickly and effectively. Humidity sensors are integrated to optimize treatment times. The drying process can be precisely adjusted to the part spectrum. Thus, only the energy actually required is consumed.

Effective fine cleaning

The system can be seamlessly integrated into the process of a WMV cleaning system, because the PFI 900 plasma cleaning system uses the WMV standard drum with a diameter of 900 mm. It is no longer necessary to transfer the bulk materials in the cleaning process. This also reduces the costs per part because only one batch carrier is used.

Plasma cleaning in the PFI 900 achieves surface tensions of ≥ 55 mN/m, at a throughput rate of up to 250 kg per cycle and completely without the use of harmful chemicals. A fully automated process sequence, controlled by the higher-level master computer, increases the efficiency of the ultra-fine cleaning process. The PFI 900 thus offers its users the opportunity to significantly improve their eco-balance by eliminating final chemical cleaning and reducing CO² emissions.

Discharge in a metered manner

As with loading, the focus is also on material protection and batch separation during emptying. Individual adaptation to a wide variety of customer containers is realized by the WMV unloading system; interlinking of subsequent processes is also possible.

Conclusion

Due to the WMV modular system, the PFI900 plasma fine cleaning system from aixACCT can be perfectly integrated. We offer flexible, highly efficient and environmentally friendly cleaning systems, which are always individually tailored to the customer’s requirements in terms of performance and parts spectrum. Top priority in our plants is given to performance, material conservation, energy saving, environmental protection and flexibility. The modular system also offers the possibility to start with a basic plant in order to retrofit the automation at a later stage.

| Basic data | PFI 900 |

|---|---|

| Container type | Special drum |

| Basket size | DM 900 x 650 |

| Number of baskets | 1 |

| Bulk material Weight Total up to | 250 kg |

| Bulk material Total volume approx | 90 L |

| Mounting | Top |

| Mounting type | Crane fully automatic, process integrated |

| Typical application | Robust parts, metal or plastic |

| Typical throughput | |

| Surface tension at typical cycle time | 55 mN/m |

| Power | 35 kW |

| Process gas | Oxygen (nitrogen, argon) |

| Pump-down time dry empty approx | 150 s |

| Footprint | 4 x 3 m |